This is achieved by merging various production apps in a global control center, which…

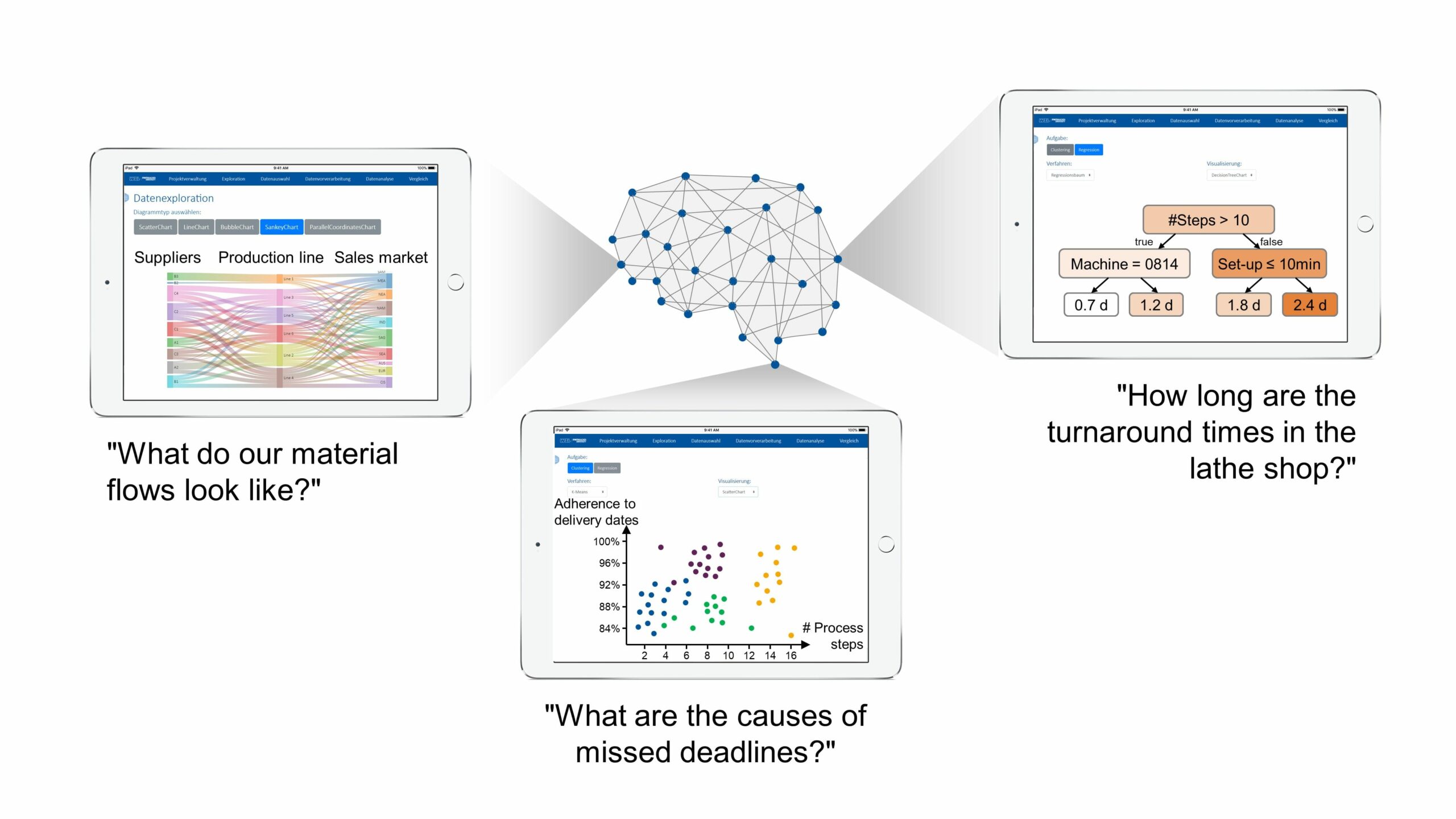

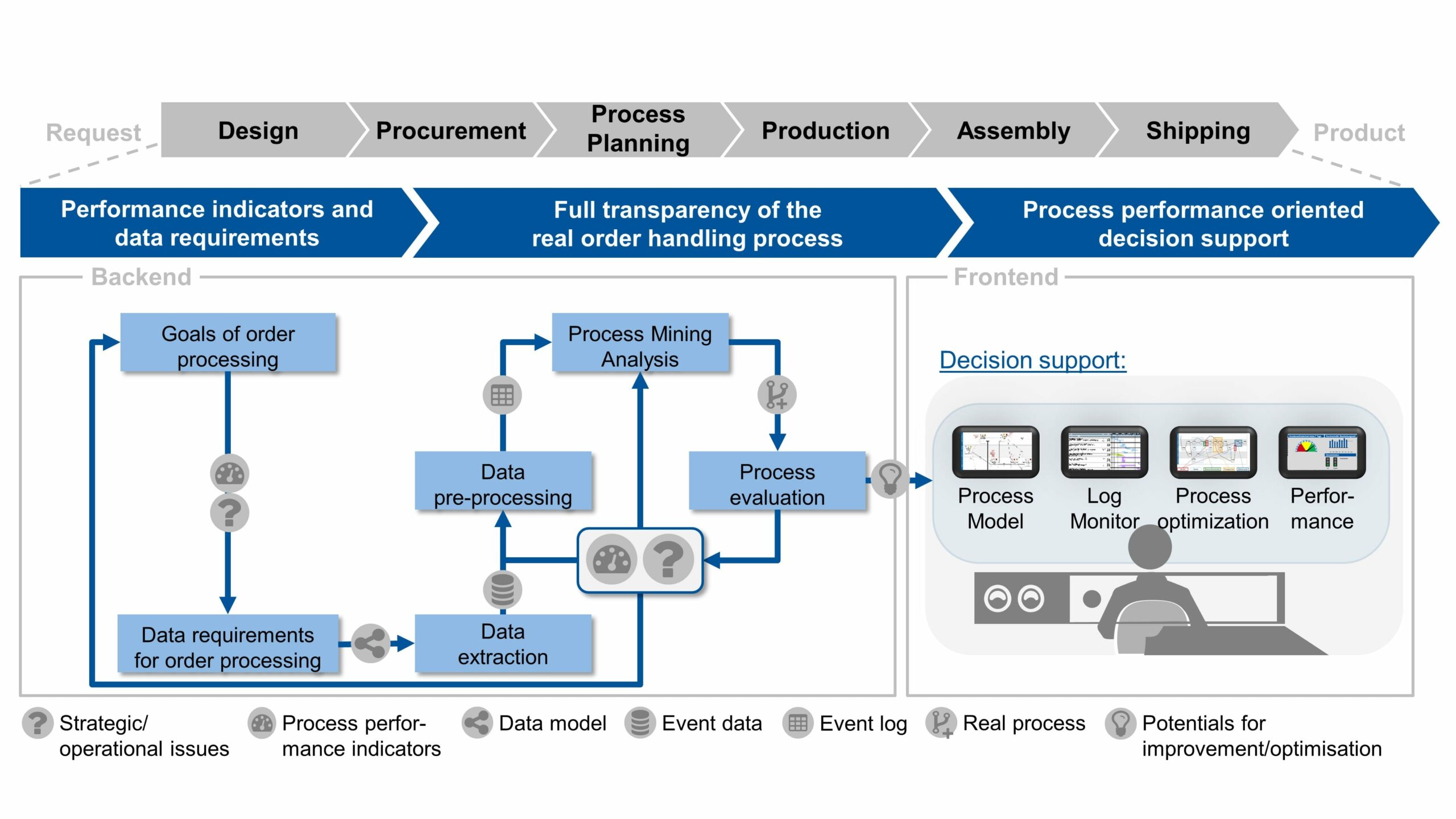

Process-independent applications of Process Mining will significantly enhance the process efficiency increases achieved to date. The GPMC is therefore exploring the possibilities of an adaptation of Process Mining across the entire order handling process in collaboration with Prof. Dr. Van der Aalst – the founder of the Process Mining discipline. The objective is to compare the challenges of this innovative topic with the requirements of manufacturing companies and to transfer the findings back into research:

There are many reasons for the low utilization of AI: complex processes, bad data quality and permanent cost pressures make AI products appear uncertain, which means they don’t get approved. Taking a closer look at these reasons, however, it soon becomes clear that AI is not the problem – it is the right answer. When AI is used properly, process complexities can be managed efficiently. AI can heal insufficient data quality with statistics and help decision-makers achieve significant cost savings. What is needed is a clear understanding of what AI can and can’t do, and a vision for actively involving employees in the data evaluation process to ensure that they can trust AI results and use them accordingly.

The offering of the GPMC for manufacturing companies is an application-oriented examination of the topic AI, an uncomplicated way to gain experience quickly and achieve good results. To that end, the GPMC examines success factors and best practice for dealing with AI and translates these into a structured and methodically secured procedure. Do you have the feeling that you keep having to start from scratch and still don’t get anywhere despite huge efforts? Contact us with regards to research and/or consulting projects, or seminars on the topic of AI.